kawasaki fd620d service manual pdf

General Information

The Kawasaki FD620D is a 4-stroke, liquid-cooled v-twin gasoline engine, featuring a pressurized lubrication system and transistorized ignition. It delivers 20.0hp at 3600rpm, with a displacement of 617cm³.

1.1 Model Identification

The Kawasaki FD620D engine is a 4-stroke, liquid-cooled, v-twin gasoline engine, identified by its model code FD620D. It is commonly used in various applications, including Argo ATV models such as the Conquest 6×6 and 8×8. The engine features a displacement of 617cm³ and produces 20.0hp at 3600rpm. Specific model identifiers include FD620D-AS02 and FD620D-AS17, with serial numbers ranging from 8900001-8999999. The service manual for this engine is divided into three parts, totaling 138 pages, and covers sections such as general information, periodic maintenance, and troubleshooting. The manual is essential for proper servicing and maintenance, ensuring optimal performance and longevity of the engine.

1.2 General Specifications

The Kawasaki FD620D engine is a 4-stroke, liquid-cooled, v-twin gasoline engine designed for reliable performance. It features a displacement of 617cm³ and delivers 20.0hp at 3600rpm. The engine utilizes a pressurized lubrication system and transistorized ignition for efficient operation. It is equipped with an ejector cooling system and a full warning system for enhanced functionality. The service manual for this engine is divided into three parts, totaling 138 pages, and includes detailed specifications for proper maintenance and servicing. The FD620D is widely used in applications such as Argo ATV models, including the Conquest 6×6 and 8×8, and is supported by genuine Kawasaki parts and tools for optimal performance.

Periodic Maintenance

Regular maintenance is crucial for optimal performance. Follow the Periodic Maintenance Charts for specific regions and refer to torque specifications in the service manual for guidance.

2.1 Periodic Maintenance Chart (Except U.S.)

Regular maintenance is essential to ensure the longevity and optimal performance of the Kawasaki FD620D engine. The periodic maintenance chart outlines specific tasks to be performed at designated intervals, typically every 50 hours or 6 months, depending on usage. Key tasks include oil and filter changes, air cleaner servicing, spark plug inspection, and valve clearance checks. Additionally, the chart recommends inspecting the fuel system, cooling system, and lubrication system for any signs of wear or damage. It is crucial to adhere to these schedules to prevent premature wear and ensure reliability. Always refer to the official service manual for detailed procedures and specifications. Proper maintenance will help maintain the engine’s efficiency and prevent unexpected breakdowns.

2.2 Periodic Maintenance Chart for U.S.

The U.S.-specific periodic maintenance chart for the Kawasaki FD620D engine outlines essential tasks to ensure optimal performance and longevity. Maintenance intervals are typically every 50 hours or 6 months, depending on usage conditions. Key tasks include oil and oil filter replacement, air cleaner servicing, spark plug inspection, and valve clearance checks. Additionally, the chart recommends inspecting the fuel system, cooling system, and lubrication system for wear or damage. It is crucial to follow these schedules to maintain engine efficiency and prevent unexpected issues. Always refer to the official service manual for detailed procedures and specifications. Adhering to this chart will help ensure the engine remains reliable and operates within factory specifications, while also maintaining warranty validity for U.S. models.

2.3 Torque and Locking Agent Specifications

The Kawasaki FD620D engine requires precise torque specifications for various components to ensure proper assembly and performance. Cylinder head bolts should be torqued to 44 N·m (32.4 ft·lb) in a staggered sequence, while connecting rod bolts are specified at 39 N·m (28.8 ft·lb). Crankcase bolts require 34 N·m (25.2 ft·lb) of torque. Locking agents are essential for critical fasteners, with a high-strength, non-permanent locking agent recommended to prevent loosening under vibration. Proper torque and locking agent application ensures engine reliability and longevity. Always refer to the service manual for detailed procedures and tightening sequences to avoid damage or premature wear. Compliance with these specifications is crucial for maintaining warranty validity and optimal engine operation.

Fuel System

The Kawasaki FD620D fuel system includes components like the governor link mechanism, carburetor, intake manifold, fuel pump, and air cleaner, ensuring efficient fuel delivery and engine performance.

3.1 Governor Link Mechanism

The governor link mechanism in the Kawasaki FD620D engine plays a crucial role in maintaining consistent engine speed. It connects the governor to the throttle, ensuring that the engine operates within a predetermined RPM range. This mechanism is essential for preventing over-revving, which can cause engine damage. The governor link is designed to adjust the throttle valve based on engine load, providing smooth power delivery. Proper adjustment and maintenance of this component are vital to ensure optimal engine performance and longevity. Regular inspection and lubrication of the link are recommended to prevent wear and tear. If the link becomes worn or damaged, it should be replaced promptly to avoid any potential issues with engine speed regulation.

3.2 Carburetor Specifications

The Kawasaki FD620D engine utilizes a carburetor designed to deliver precise fuel-air mixture for optimal performance. The carburetor features adjustable jets and a float-type fuel feed system, ensuring consistent engine operation under various loads. It is equipped with an air cleaner system to filter incoming air, enhancing fuel efficiency and reducing contamination. Regular cleaning and inspection of the carburetor are essential to maintain proper function. The service manual provides detailed specifications for jet sizes, float levels, and adjustment procedures. Proper maintenance ensures reliable engine starting, smooth idle, and efficient power delivery across the RPM range. Always use genuine Kawasaki parts for replacements to maintain factory specifications and performance.

3.3 Intake Manifold Details

The intake manifold on the Kawasaki FD620D engine is designed to distribute the air-fuel mixture evenly to the cylinders, ensuring efficient combustion. Constructed from durable aluminum alloy, it is lightweight and resistant to corrosion. The manifold features a smooth internal design to minimize airflow restriction, enhancing engine performance. It is connected to the carburetor via a rubber intake hose, which is secured with clamps to prevent leaks. The manifold is bolted directly to the engine block, with gaskets ensuring a tight seal. Proper torque specifications for the mounting bolts are provided in the service manual to maintain integrity. Regular inspection and cleaning of the intake manifold are recommended to prevent dust and debris buildup, which could affect engine efficiency and performance.

3.4 Fuel Pump Operation

The fuel pump in the Kawasaki FD620D engine is a mechanical-type unit located inside the fuel tank. It operates by creating low pressure to transfer fuel from the tank to the carburetor. The pump features a check valve to prevent fuel backflow and a filter to ensure clean fuel delivery. Operation is tied to engine crankshaft rotation, delivering fuel only when the engine is running. If the pump fails, the engine may not start or stall during operation. Regular inspection of the fuel pump is recommended, with replacement of worn or damaged components. Ensure the fuel filter is replaced every 200 hours of operation to maintain optimal performance and prevent fuel system issues.

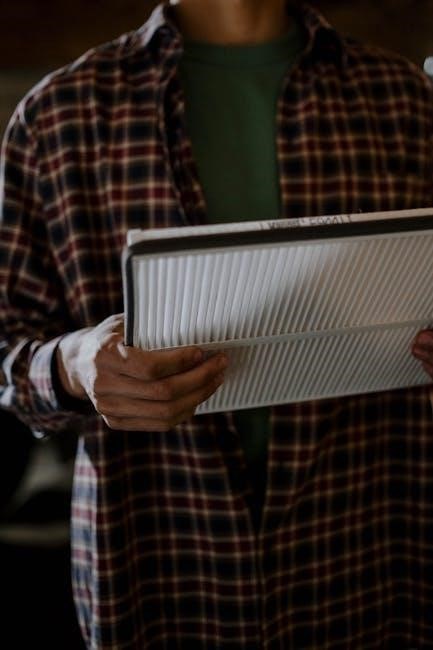

3.5 Air Cleaner System

The Kawasaki FD620D engine is equipped with a dual-element air cleaner system designed to ensure clean air intake. The system consists of a primary filter and a secondary filter, both housed in a shared casing. The primary filter captures larger debris, while the secondary filter handles finer particles, ensuring maximum protection for the engine. Regular inspection and maintenance of the air cleaner are essential, as a dirty or clogged filter can reduce engine performance and fuel efficiency. The service manual recommends cleaning or replacing the air cleaner elements every 100 hours of operation, or more frequently in dusty environments. Proper maintenance of the air cleaner system is crucial to maintain optimal engine performance and longevity.

Cooling System

The Kawasaki FD620D features a liquid cooling system with a radiator and circulating coolant to maintain optimal engine temperature. The system includes a thermostat and water pump for efficient operation.

4.1 Radiator and Cooling Mechanism

The Kawasaki FD620D engine utilizes a liquid cooling system, with a radiator as the primary heat exchanger. The radiator is designed to efficiently dissipate heat from the coolant, ensuring optimal engine temperature. A water pump, driven by the engine, circulates the coolant through the system. The coolant flows through the engine block and cylinder head before returning to the radiator. The system also includes a thermostat to regulate coolant flow and maintain the ideal operating temperature. Proper maintenance, such as checking coolant levels and inspecting hoses for damage, is essential for reliable performance. The radiator’s cooling capacity ensures consistent engine operation under varying load conditions, preventing overheating and potential damage to internal components. Regular cleaning of the radiator fins is recommended to maintain airflow and cooling efficiency. Always use the specified coolant mixture to avoid corrosion and ensure proper system function.

4.2 Hose and Coolant Specifications

The Kawasaki FD620D engine requires a 50/50 mixture of distilled water and antifreeze for optimal cooling performance. The coolant should meet ASTM D4985 standards to prevent corrosion and ensure longevity. The radiator hoses are constructed from durable rubber compounds to withstand high-temperature and pressure fluctuations. Regular inspection of the hoses for cracks, leaks, or signs of degradation is essential. The coolant system is designed to maintain consistent engine temperatures, with a thermostat that opens at approximately 82°C (180°F). Proper coolant levels should be maintained to prevent overheating or engine damage. It is recommended to use genuine Kawasaki coolant to ensure compatibility and system performance. Regular draining and flushing of the cooling system, as outlined in the service manual, are crucial for maintaining efficiency and preventing corrosion. Always follow the specified torque values when connecting hoses to avoid damage to the system.